How to Create a DIY 3D Printer

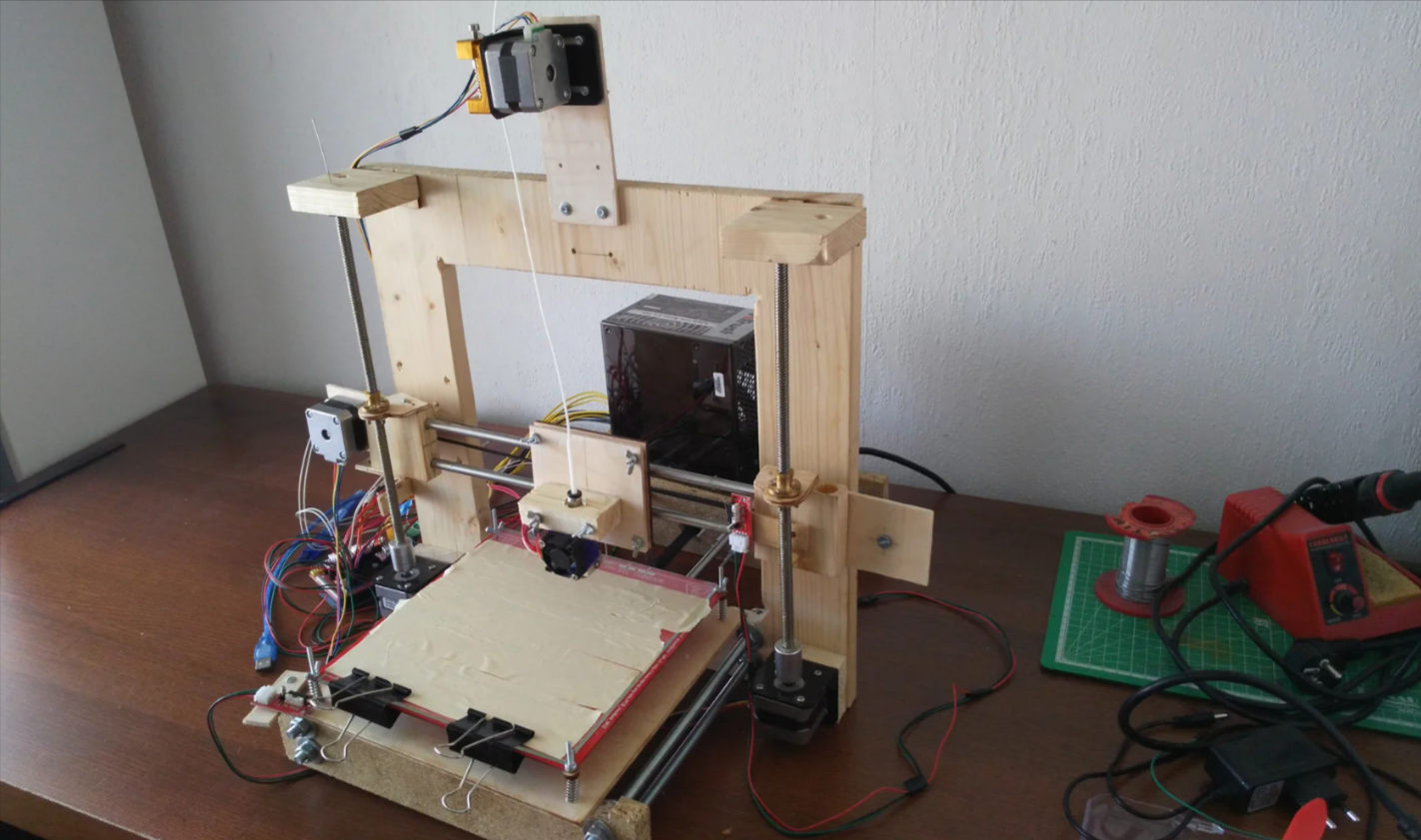

You can create your own 3D printer and build it to suit your requirements; this is a very nice way to learn about 3D printing while still saving money!

Your printer needs a controller board along with other essential parts, while igus(r) components guarantee reliable support to create effective machines.

1. Choose a Design

Before you begin building your 3D printer, design it. Hundreds of DIY examples exist, covering everthing from confirmation-of-concept basic FDM printers up through industrial grade SLA models; choice is of course heavily dictated by budget and the sought-after print quality.

Designing a maker might look daft at first, but spending a while thinking about all arrangements will eventually find one that fits. Consider the purpose and operation, perform some back and forth reviews, and get to a comfortable decision. As soon as possible make all specifications available for use in the construction of the printer.

Safety always comes first with regard to the design that you might have selected. First eliminate any external exposure of wires.

Part of your printer setup is putting in consideration an enclosure because of the benefits. First, it controls the temperature and reduces the fumes within while blocking the noise interference that would disturb your prints. There are plenty of an assembled DIY printer enclosure options that can be made just with readily available materials.

2. Construct Your Printer

Now that you have your design for the 3D printer, the next step is to build it. There are many different options to constructing it: one can purchase ready assembled machines, or build it from scratch using a DIY kit and sourcing all parts herself. Either way, however, one must take their time building a good foundation for it so that it works efficiently and brings pleasure.

Choose a kit or build plan with clear documentation in order to limit errors and issues when assembling or troubleshooting your machine, as this can help minimize issues during assembly/troubleshooting and avoid common mistakes which could potentially prevent printing altogether.

When buying parts for the printer, select the complete set. It saves time and labor, no running after extra parts those may or may not be needed.

Putting together your very own printer calls for working with circuits and electrical components that sometimes cause burns or shocks so close by should be a fire extinguisher of the right kind for electrical fires just in case accident happens and make sure to routinely check on them to see if there might be any signs of overheating or electrical problems.

3. Print Your First Object

You now know how to conceive designs for objects that can be printed; it's time to unleash one's creativity! Get oneself some more complex designs and experiment with different materials to get that mastery into shaping one's nest with technology.

Convert STL files into G-code using a slicer software program. G-code is the language of 3D printers. A slicer simulates a print in real-time watching for clogs or warping, even early on, to be able to fix it in real-time.

Consult the appropriate guide furnished with your printer to achieve proper setup, calibration, and maintenance of the apparatus before you start creating things!

The printer should go under proper grounding to mitigate dangers of electric shock and mechanical failures. Make sure all wire insulations attach well and employ cable ties when necessary to keep things out of moving parts or away from dust accumulations.

Periodic maintenance is another thing that ensures efficiency in the running of the printer, like checking the temperature of the extruder, replacing worn plastic parts, checking the suitability of the fit of your Bowden tube, and also leveling the bed to have high-quality prints without uneven prints or issues concerning these uneven prints times.

4. Seek Help

With increasing use and knowledge of the 3D printer, some assistance will be expected in its usage. Relevant resources for online help are plentiful. Instructables has some great guides; useful videos at YouTube and TechBuilder; there are even forums and Discord channels to help users manage their printers.

Digi-Key also has some good supplies and on-line filaments for 3D printing as well as providing great customer services to answer any query.

If you are using the printer for the first time, always make sure that you have read every manufacturer's instruction closely as it is very critical in the setting of each device. This ensures that your print comes out exactly the way you wanted it while using the suitable filament for that model. Lubricate moving parts as appropriate - reduce friction and improve printing quality.

Once everything has set up, and you are finally confident about its usage, now you can try making these unique objects! From very effective tools to stunning works of art and sculpture, the uses of such wondrous machines are endless-the only limit is your creativity!